- Major and minor two injection components, can inject synchronously or inject alternately by two screw bars controlled by professional programmable coputer, the products have colorful attractive appearance.

- The sandwich product manufacturing are available too, can reduce the cost.

- Vast application range in two color forming, the raw material include PP, PE, PS etc.

- Products application: Keystokes, Knobs Switches, Fastener, Hand tools, Power tools, Electrical appliance, Daily-use products, containers, cartons, toothbrushes, stationery, auto parts, poker chips and so on.

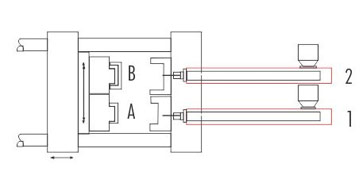

Turnplate type clear two-color injection molding machine contains two sets of parallel arranged injection units and is equipped with hydraulic motor or rotary platen device (turnplate) driven by servo motor.

Main Features:

- Modularized design for the whole machine, the clamping unit and injection unit can be combined by splicing.

- Two set of independent parallel arranged injection units. They can be customized according to the required injection weight of the products.

- The screw and barrel are made of imported high quality alloy steel. After ion nitriding processing, it has the corrosion - resistant, abrasion - resistant and long life time characteristics

- You can select the specialized screw in accordance with the characteristics of engineering plastic.

- Two sets of injection units can do the injection of the some time. Once molding for two color products greatly shortens the molding cycle.

- The clamping unit adopts the involute ablique five-pivot crank-type clamping structure. The parameter are confirmed after optimized by the specialized computer software.

- Two sets of independent hydraulic ejection system, there are several ejection methods for you to choose from.

- Operating position and double - direction 180 degree moving platen tumplate is equipped with the high - performance directional valve to control the hydraulic motor for Servo motor drive, and the rotational mold pressure and speed are controlled separately to ensure the speediness, stability and accuracy of the rotational mould.