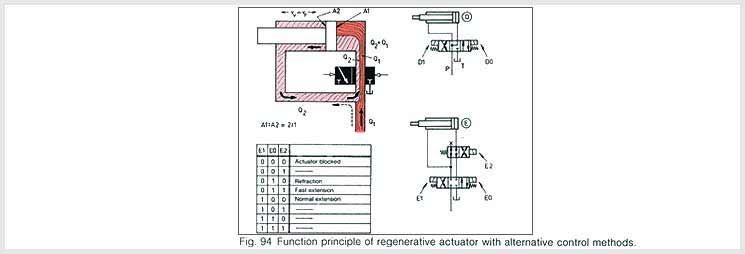

Regeneration is achieved by using

suitable valving which connects the exhaust flow from the extending piston

rod with the in-rushing fluid on the piston end. Hence, the exhaust fluid,

which would normally return to tank joins the fluid flow from the pump.

Thus, the piston rod is extended with increased speed.

For example, if the full piston area (A1) has a ratio of 2:1 to the annulus

area (A2), then the piston rod will extend and retract with equal speed.

During the regeneration process, equal pressure acts on both sides of the

piston. Thus, the extension force is the product of the piston rod area and

the system pressure. Retraction stroke has a similar calculation as the

annulus area and the rod area are equal (with a 2:1 ratio)

Thus, the forces for extension and retraction are equal. With a 2:1 ratio,

the exhaust volume of the pushed-out fluid during extension is one half of

the volume formed by the full piston area (A1). Thus, the other half must be

filled by the pump. Hence, the regenerated, volume is equal to the pumped

volume (VR = VP). Therefore, the 2:1 ratio between regenerative control with

a piston-to-rod area, provides equal speed and equal force for extension and

retraction. The control circuit (D) permits the actuator to extend with

normal speed if signal D1 is selected, or to extend rapidly (regenerative

flow condition) if the valve's center configuration is selected. With signal

D2 the actuator retracts with normal speed.