|

Our Product Range

|

|

|

Home »

Info

Center » Fluid Flow

Fluid Flow

The fluid in a hydraulic system is

normally under pressure and completely fills the pipes of the system. This

pressure may result from friction within the piping system, from gravity or

the weight of the fluid, or from load resistance to the pump flow.

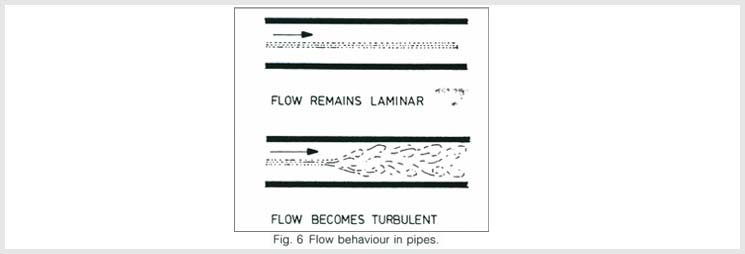

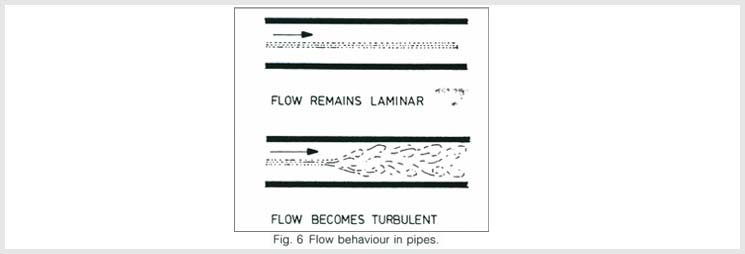

When a hydraulic fluid flows through straight piping at low velocity, then

the particles of the liquid move in straight motion parallel to the

direction of flow, so that heat loss due to friction is minimal. Such flow

is referred to as laminar flow. Detrimental factors such as high flow

velocity, sharp bends and elbows in the piping, rough internal pipe

surfaces, etc. cause cross currents within the flow and turbulence starts to

develop. Turbulent flow causes significant increases in friction and a

pressure drop; thus heat is produced (input energy is wasted).

Although friction can never be eliminated entirely, it can be reduced to

some extent if the aforementioned detrimental factors are avoided or reduced

(fig. 6).

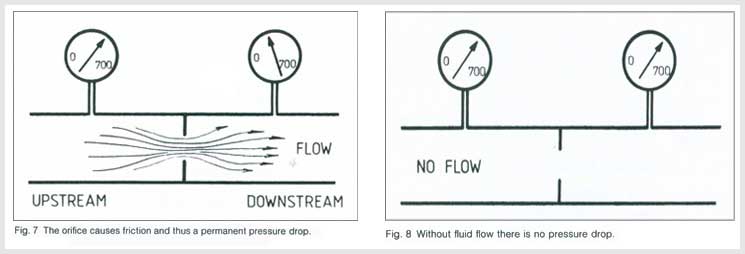

Flow through an orifice

An orifice is a hole, narrower than the

pipes to which it is fitted. The orifice is generally used to control flow,

or to create a pressure differential.

As long as there is flow through an orifice, there exists a pressure drop

across the orifice, which means that the pressure downstream — that is,

in the direction of flow (fig. 7) — is less than the pressure upstream.

There is permanent loss of pressure since the friction (work) has been

transformed into heat, and this heat cannot be regained. As soon as the flow

is stopped the Law of Pascal must be applied for the now static condition,

and pressure on both sides of the orifice equalise (fig. 8)

Flow rate and flow velocity

The average speed with which the

particles of a fluid move past a measuring point is called fluid velocity or

speed. The fluid velocity is measured in metres per second (abbreviated

m/s). Flow velocity must be carefully controlled and considered when the

hydraulic system is designed, as an excessive flow velocity causes turbulent

flow with its resulting high pressure drop.

Flow rate is the measure of flow volume that streams past a measuring point

in a given time. Flow rate is measured in litres / second (abbreviated Us)

or cubic metres per second. (The latter is less frequently used.) Flow rate

has a direct bearing on the speed with which a hydraulic actuator moves a

load and is therefore governed by the design concepts of the machine.